Wood-Plastic Composite (WPC): Material Characteristics and Outdoor Applications

Shandong Unique International Trade Co.,Ltd

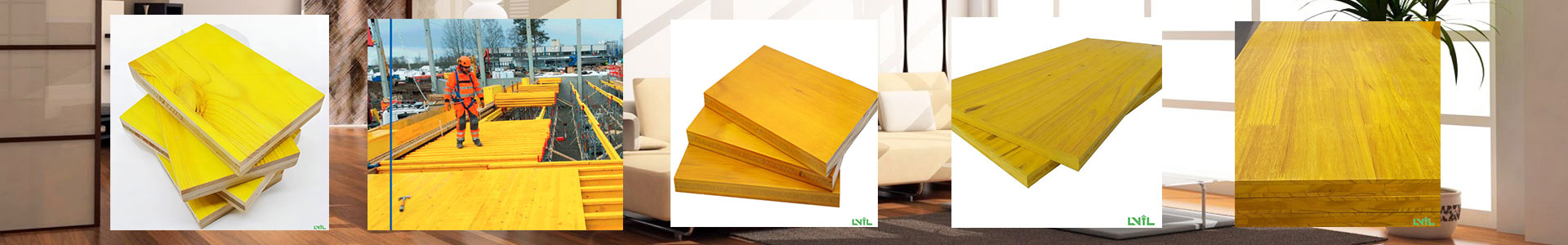

Wood-Plastic Composite (WPC) represents a category of engineered materials that combine wood fibers or natural fillers with thermoplastic polymers. These composites have gained widespread adoption in outdoor construction applications, including decorative wall panels, exterior doors, and flooring systems. This article examines the distinctive material properties and typical product applications of outdoor WPC solutions. Unique

1. Key Material Advantages of Outdoor WPC Unique

1.1 Environmental Sustainability

WPC formulations align with circular economy principles by utilizing recycled polymers (HDPE/PP) and agricultural byproducts (wood flour, rice husks) as primary feedstock. This substitution strategy reduces virgin timber consumption while diverting plastic waste from landfills. Manufacturing processes adhere to eco-design criteria, producing VOC-free products with recyclability and partial biodegradability.

1.2 Enhanced Mechanical Performance

Through advanced compounding techniques, WPC achieves superior strength-to-weight ratios compared to conventional plastics. Hot-press molding with polymer nanomaterials and wood fiber reinforcements yields products with:

Powered by Shandong Unique International Trade Co.,Ltd

- 2-3x higher flexural modulus than unmodified plastics

- Wood-like texture retention with improved hardness (Shore D >70)

- UV stabilization for extended outdoor exposure (≥10 years service life)

1.3 Dimensional Stability

The composite matrix demonstrates exceptional resistance to environmental degradation: Copyright © Shandong Unique International Trade Co.,Ltd All Rights Reserved.

- Low water absorption (<1% volume expansion)

- Thermal expansion coefficient matching traditional lumber

- Maintains structural integrity across -40°C to 80°C temperature ranges

2. Representative Outdoor WPC Products Shandong Unique International Trade Co.,Ltd

2.1 Decorative Wall Panels

These architectural cladding solutions offer: https://www.3plyplywood.com

- Realistic wood grain replication through co-extrusion technology

- Lightweight construction (density 1.1-1.3 g/cm³) enabling DIY installation

- Corrosion resistance to salt spray and atmospheric pollutants

Ideal applications include villa facades, balcony enclosures, and commercial boardwalks.

2.2 Performance WPC Doors

Engineered for exterior use, these doors integrate:

Unique

- Microcellular foaming technology (density reduction up to 30%)

- Multi-layer co-extrusion for weatherproof seals

- Flame retardancy (class B1 rating per GB 8624)

Key features include: - Formaldehyde-free formulation (E0 emission standard)

- 20-year warranty against warping/delamination

- Resistance to fungal decay and termite infestation

2.3 High-Traffic WPC Flooring

Specifically designed for pedestrian surfaces, this product category provides: www.3plyplywood.com

- Abrasion resistance (Taber test >10,000 cycles)

- Anti-slip surface treatment (R11 rating per DIN 51130)

- Drainage channel design for wet environments

Performance benchmarks include: - 95% color retention after 5,000-hour QUV accelerated weathering

- Load-bearing capacity exceeding 5 kN/m²

- Compatibility with pedestrian and light vehicle traffic

Technical Note:

Modern WPC formulations incorporate coupling agents (maleic anhydride grafted polymers) and UV absorbers (benzotriazole derivatives) to optimize interfacial adhesion and photo-oxidation resistance. These additives enable compliance with stringent outdoor durability standards (ASTM D7032, EN 15534).

https://www.3plyplywood.com