Before going to shopping malls or dealers to buy plywood, for convenience just sit at home and access the Internet and find out. However, buying plywood online often has a lot of questions from customers. Unique would like to summarize the commonly asked questions of buyers for everyone to refer to before choosing to buy for themselves the right plywood type. Let's find out right below! Unique

Shandong Unique International Trade Co.,Ltd

Shandong Unique International Trade Co.,Ltd

10 FREQUENTLY ASKED QUESTIONS WHEN BUYING PLYWOOD AND ANSWER

1. When was plywood invented? Who invented it?

Plywood was introduced to the United States in 1865 and industrial production began shortly thereafter. In 1928 the first standard 4 ft x 8 ft (1.2 m x 2.4 m) plywood panels were introduced in the United States for use as general construction materials.

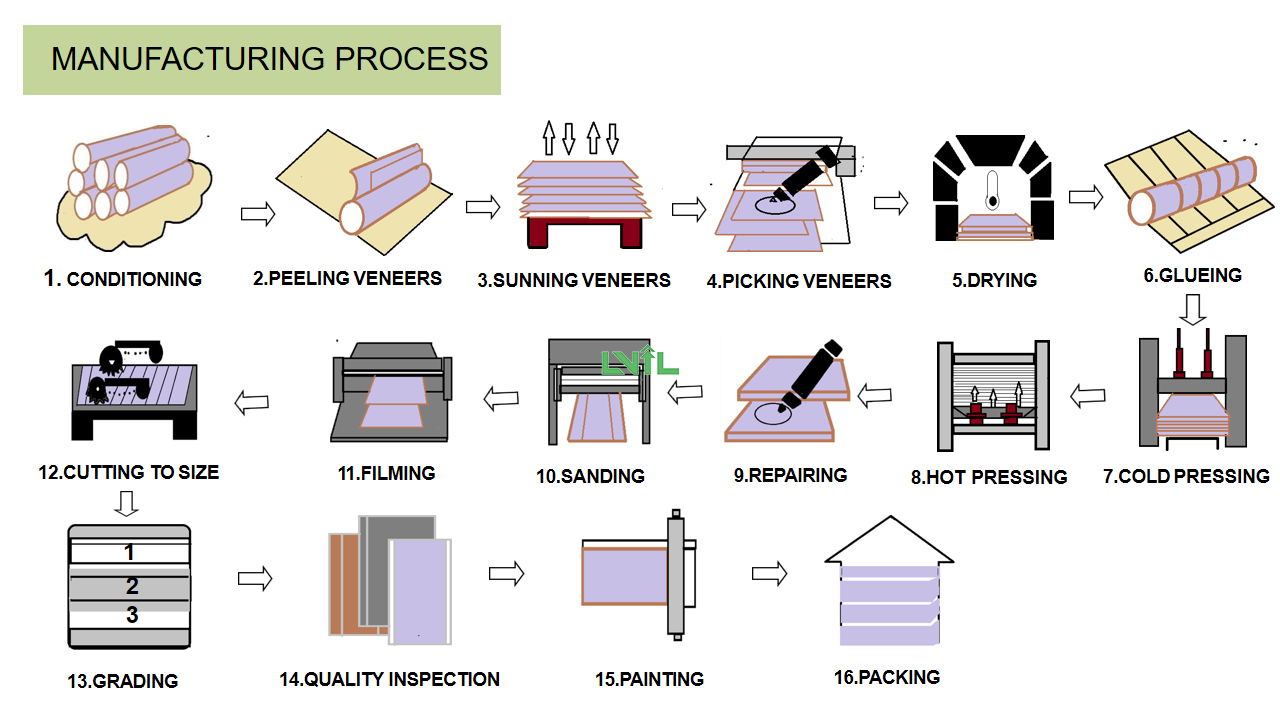

2. How is plywood made?

Copyright © Shandong Unique International Trade Co.,Ltd All Rights Reserved.

Copyright © Shandong Unique International Trade Co.,Ltd All Rights Reserved.

Plywood, a versatile engineered wood product, is manufactured through a multi-step process that maximizes wood utilization and enhances structural integrity. The production begins with rotary peeling of logs into continuous veneer sheets, which are then dried using automated systems to achieve optimal moisture content. These veneers are coated with adhesives and assembled in alternating grain directions—a technique called "cross-banding"—to improve dimensional stability and strength. After cold pressing to align the layers, the assembled boards undergo hot pressing under controlled temperature and pressure to cure the adhesive, ensuring牢固 bonding. The final product is sanded, graded, and stamped based on criteria such as grain quality, density, and thickness. https://www.3plyplywood.com

Key Applications of Plywood

Plywood's adaptability stems from its balance of strength, cost-efficiency, and workability. Common uses include: Shandong Unique International Trade Co.,Ltd

- Construction: Interior/exterior cladding, formwork, roof decking, and wall sheathing due to its resistance to warping and moisture (depending on grade).

- Furniture: Bed frames, cabinets, and decorative panels, where its smooth surface accepts finishes like veneers or laminates.

- Specialized Industries: Marine-grade plywood for boat hulls, railway carriage interiors, and packaging solutions requiring durability.

Sustainability and Recycling

Untreated plywood (free of paints or chemicals) can be repurposed through several pathways:

- Reprocessing: Ground into wood fiber for new plywood or particleboard.

- Composting/Mulch: Organic breakdown into soil conditioners.

- Animal Bedding: Shredded for livestock housing.

- Reclamation Projects: Stabilizing soil in landscaping or erosion control.

End-users may also repurpose intact plywood scraps for DIY furniture, though aesthetic consistency may vary.

Environmental Resistance and Maintenance

While plywood resists moderate moisture exposure, prolonged water contact can lead to degradation:

- Water Resistance: Film-coated or marine-grade plywood (Type I: weather/boil-proof) withstands prolonged wet conditions better than standard grades.

- Damage Risks: Untreated plywood is prone to delamination, warping, and rot if left exposed to humidity without protective sealants.

Flexibility and Processing

- Bending: Possible with thin sheets (e.g., 3–6 mm) using heat treatment or steam bending, though excessive curvature risks cracking. Hardwood veneers like eucalyptus or oak offer better flexibility due to tight grain structures.

- Finishing: Plywood accepts staining, sanding, and polishing. Use 80-grit sandpaper for initial leveling, followed by finer grits (120–220) for a polished finish. Avoid excessive force to prevent veneer tear-out.

Thickness and Customization

Standard plywood thicknesses range from 3 mm to 18 mm, with specialized grades available up to 25 mm. Thicker variants (e.g., 18 mm) are preferred for structural applications like flooring or load-bearing furniture, while thinner sheets (3–9 mm) suit cabinetry or laminates.

Copyright © Shandong Unique International Trade Co.,Ltd All Rights Reserved.

Addressing Common Concerns

- Staining: Achieving uniform color requires pre-sanding and even application of pigments. Post-sealing stains may yield patchy results if not carefully managed.

- Durability: Proper sealing and maintenance extend plywood's lifespan, particularly in high-humidity environments.

In summary, plywood remains a cornerstone of modern construction and design, offering a sustainable, cost-effective solution for diverse applications when matched to the appropriate grade and treatment.